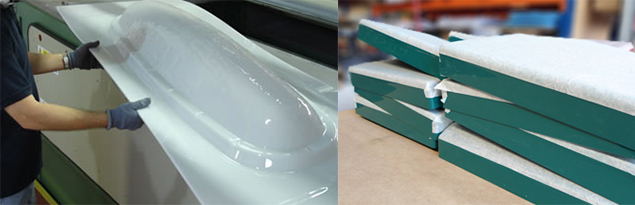

First of all, Fibreglass is less expensive and more adaptable than carbon fibre. Also it is more grounded than numerous metals by weight, and can be formed into complex shapes. Applications incorporate airship, pontoons, vehicles, and baths and fenced in areas, swimming pools, hot tubs, septic tanks, water tanks, material, channels, cladding, throws, surfboards, and outside entryway skins. An individual auxiliary glass fibre is both solid in strain and pressure that is, along with its pivot but at FORMING PLASTICS replacement of glass fibre is done for over a decade. Plastic Vacuum Forming offers several advantages over fibreglass like the Most cost effective in production volume. Furthermore Up to 35% Lighter. Hence both final thermoformed parts and excess material are fully recyclable. Thermoforming can support the tight tolerances and complex geometries necessary to create mating parts. It has more durability than fiberglass.

Vacuum Forming offers low-cost tooling. Parts can be easily painted or formed in different colors. Consistency of part is more. Since the process uses low pressures, the mould can be of inexpensive materials. Mould fabrication time can be reasonably short. Likewise, it offers several processing advantages over other forming processes like low cost, ease of tooling, efficiency . One of the main benefits of vacuum forming is the speed at which tooling can be produced.